Are You Using the Right Upholstery Supplies?

How do I know which upholstery supplies are the right ones?

Have you ever gone to a store searching for a new product that you really know nothing about? Not a good feeling is it!?

Well shopping for supplies to use in your upholstery project when you’ve never done this before, or have only put new fabrics over the old padding before (a big no-no in my studio) can be just as confusing. If you come from a sewing background you may hear the same terms but when the supplies are for upholstery a quilt batting doesn’t fit the bill and cotton is not what you use for quilting either. So let’s talk about the right supplies for your upholstery project. You know how important it is to use the right tool for the job already…if you don’t you’ll want to read this post: Tools tools and more upholstery tools.

Note: Some of the links in this blog post may be affiliate links. Should you buy products using these links I may receive a small commission.

Burlap

Jute Webbing

Sagless

Do you know which webbing to use for your project?

There are some supplies that you are already familiar with such as burlap, muslin or even jute webbing.

- Burlap: Burlap is burlap and you really can’t go wrong there as long as you are using it the way it was intended, for covering your support system.

- Jute Webbing: Jute webbings are not all the same, I am sure you’ve seen the red stripe and the black stripe, on a few occasions I have come across a green stripe. So when and where do you use each of these? The black stripe is referred to as 9 pounds and is to be used as back support. The black stripe is not appropriate for use in seats that will hold the weight of a person. That is where the red stripe which is an 11 pound and meant to be used for seats. When you are upholstering you want to be sure and use the items the way they were intended to be used to ensure you have the strength where it is needed. You don’t want to have an oops when the seat falls out of a chair because someone used the wrong webbing. As for the green stripe, I have never seen it with a pound rating and my supplier does not carry, but I’ve come across it when a student has brought it to a workshop and it feels fairly thin and not nearly as strong as the red. Therefore, I would not suggest you use it for seats if you happen to have any on hand.

- Sagless: Another option for support under your springs or foam would be a product my supplier calls Sagless. This is actually a polypropylene material and tends to be hard to find in the retail market. The Sagless is used in the same manner as you would use jute webbing. As for one being better than the other, I feel they are very much the same. The Sagless (also known as Polypropylene) saves you time as you are attaching one piece where having enough jute webbing to cover an area takes several strips, therefore, is a bit more time-consuming. You can also purchase polypropylene in webbing form very much like the jute webbing.

Synthetic Cotton

Old Cotton

Cotton, cotton who’s got the cotton?

Upholstery cotton comes as a roll and is typically sold by weight. There is a 100% natural which is an off-white color and has brown flecks which are actually part of the plant. You have probably seen this product when tearing down older antique pieces. Newer furniture is not apt to have cotton at all. In newer furniture you often times see low-density foam used as padding. Foam is another topic which we will hit on a bit later. I like synthetic cotton which looks much the same as the natural except it is pure white and not a natural product but man-made. I like the feel of and working with the synthetic but both are good products. Cotton is used for padding and adding comfort to your upholstered pieces. You may also have seen the straw, horsehair, and other organic fibers when you’ve completed a teardown. Using cotton will give you a great finished product without the need of using the straw and other fibers in your piece. Heck, I have even seen old clothes used for padding in older pieces.

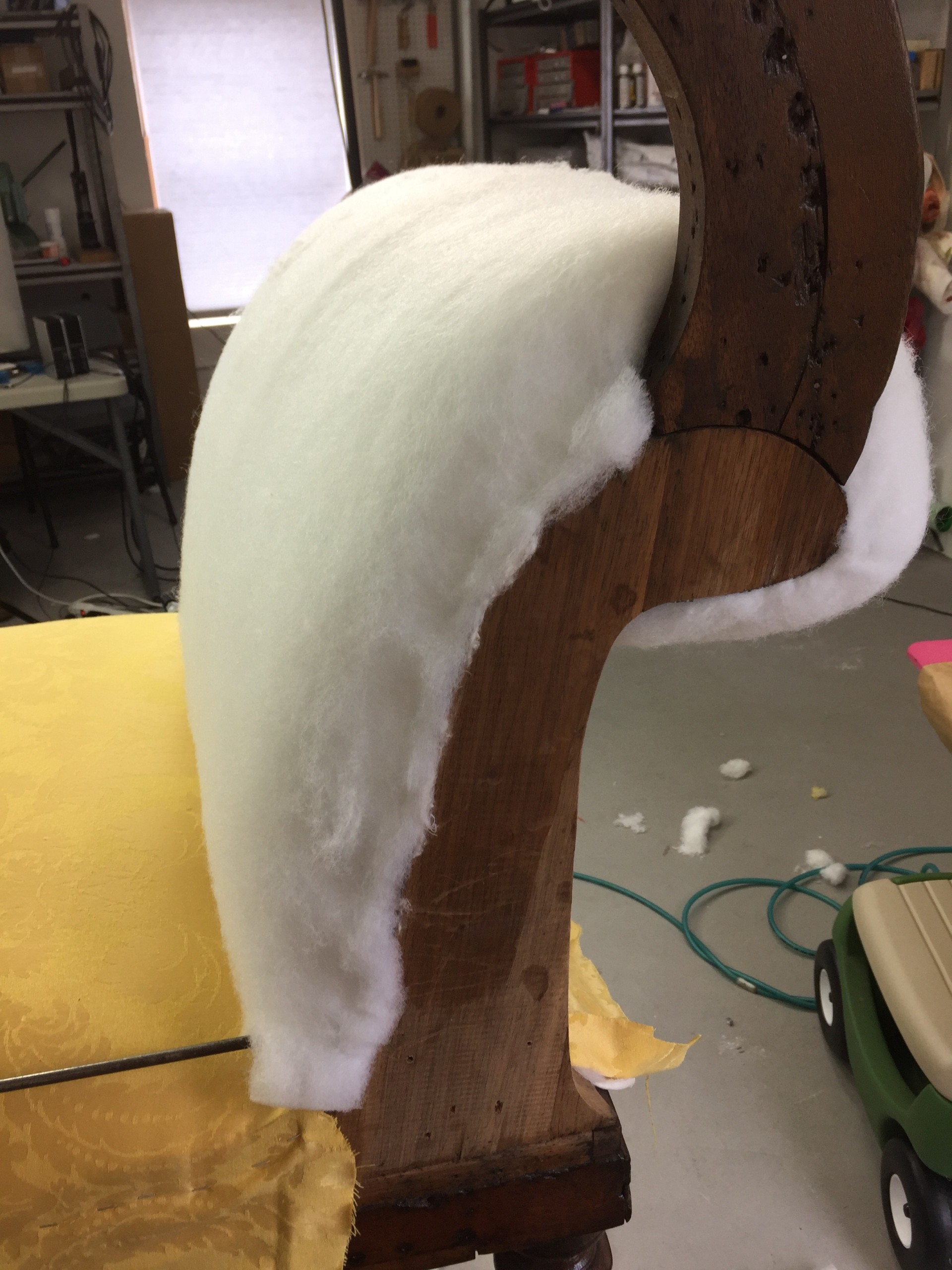

Dacron wrapped arm

Bonded Dacron Roll

Bonded Dacron

Dacron is a must in my workshop

Another form of padding you will use along with cotton is Dacron. Dacron is the brand name and the product is actually Polyethylene terephthalate, more commonly called polyester. (can you see why it is referred to as Dacron… much like hook and loop tape has become known as Velcro which is also a brand name.) Polyester comes in a few different forms. A loose form such as you would use in pillows is typically sold by the bag and often times by weight. This loose poly is fluffy, white and very soft to touch but when used in a pillow form is very supportive. Another option is a stitched from where the poly is lightly stitched to a fabric called accord. In this case, the poly is very silky feeling yet quite strong, this is commonly used to wrap cushions to give the appearance of a feather cushion. The poly that is most often used as a padding for upholstery is a bonded Dacron. This poly is thermally bonded making it very strong. Again, this comes on a roll and is 54”W and is typically more durable than what you might find in a craft store. The bonded version is used over the other paddings in upholstery and will give your furniture a very smooth finish as your final padding layer before applying your decorative fabric.

Fiber Flex Welt Cord

Cotton Welt Cord

Foam Flex Welt Cord

Cording, Piping, Welting…. which is the right term?

Let’s chat about welt cord, piping, welting, and cording. All seemingly used interchangeably. Well for this conversation I will refer to our commonly used friend as welt cording…. Is that okay? So there is a fiber flex welt cord which is a paper center surrounded by a net-like material. This is used most commonly in upholstery. The fiber flex is a bit on the stiff side but still flexible. I like the way the fiber flex works when attaching to an upholstered frame. I can bend it where needed but get a nice straight line as well. You can also use the fiber flex for cushions too. The cotton welt cord is a great product for slipcovers and pillows especially if the end product might be washed. When purchasing a cotton welt cord be sure to get the one that is in a net and not the one that is strands wrapped together with no net. This type is commonly called Mop Cord and is not easy to sew with as it squishes (getting really technical here) under the sewing machine. Next is plastic or foam flex welt cord. Foam flex is a moisture resistant product and a perfect option for anything that will be used outdoors or for marine application. When this get’s wet there are no worries and no mildew. You can find each of these welt cords available in a 5/32” which is the most commonly used size in the upholstery world. The fiber-flex and cotton welt cord can also be found in a few other sizes as well. I prefer the 6/32” fiber flex for my upholstery projects but for slipcovers and bedding I use the 5/32” cotton welt cord. I have used the foam flex for outdoor cushions but with some fabrics, I find it persnickety to sew at times… love those technical moments don’t you….hahaha

Well, I hope this has helped to take the mystery out of some of the most common upholstery supplies. In this blog post, I have talked about some of the most common items you will use when upholstering a piece of furniture. All of these supplies are used on a daily basis in my studio. From jute webbing for support, burlap, cotton, and Dacron to pad the furniture and almost every piece has welt cord as a detail. If you are unfamiliar with how to work with these upholstery supplies you may find our online membership helpful in clarifying this, as our video tutorials demonstrate how each of these items is used in the upholstery process. Stay tuned for another blog post where we will discuss more of the items used in the upholstery process.

See you on the inside,

Kim

Where do you buy the synthetic cotton batting? I’m doing my first project, a pair of very old slipper chairs which I wouldn’t have to redo but my cat had her way with them. I sometimes wonder if the horse hair inside was an attractant?!

Also, if I could send you a picture of the old foam on the seat. It was cut into wide strips and I can’t figure out why. Then it has another solid piece of foam on top. A strange technique? Thanks! Barb

Hi Barbara, Thank you for messaging me. You can purchase synthetic cotton from Genco Supply in High Point NC or Albany Foam and Supply in Albany NY. They both ship. As for your foam being in strips, they were probably using up scraps. I would use one piece. If you are on Facebook you can join our Kim’s DIY Upholstery Hangout group to post pics and questions.

See you on the inside,

Kim

Where can I purchase sagless?

Hello Stacey, Thank you so much for reading or blogs. The Sagless is a Polypropylene material and can be purchased from both Albany Foam and Supply as well as Genco Supply. We also offer a full list of suppliers available in our membership.

What type of project are you working on?

Have a good day,

Kim

I have Sue’s Upholstery in Bradley WV your site is very helpful for early upholsterer I enjoy reading comments I also use Genco for supplies and Puckett Foam for all foam and dacron

This article was really helpful!!!!!

This article is so helpful! Thank you, and I love all the technical terminology. Excellent!

Hi Mary,

Thank you for the feedback and for reading our blog.

Kim

Any idea where I can purchase Strap Springs besides Van Dykes. I need 18 1/2 , and the DIY place in Mississippi went out of business. Thanks!

Try Albany Foam and Supply out of Albany NY or Genco Supply out of Hickory NC.

Thanks for reading our blog.

Kim

This was a great find! I have an old rocker that did have cotton batting. It was replaced with poly material, Walmart stuff. :(. It’s beginning to sag and would love to replace with proper material. Comfortable rocker! Thnx. 🙂

The information on Red vs Black Jute was very helpful! Thank you! 🙂

Hello Felicia,

I am so happy you benefited from my blog post. I enjoy sharing the knowledge have gathered over the past 25 plus years so others can avoid mistakes lol.

Happy learning,

Kim

Can I join the cotton batting scraps to upholster seat cushions? I plan on using a dacron wrap.

Hello Marie, Yes it is possible to use your cotton scraps for inserts. It will be a heavy cushion and a bit for firm than foam. The dacron will help to keep it from getting lumpy.

Kim

Hi Kim

I want to recover an old poufe but having opened it, I’ve discovered it’s made of a straw bale, basically. Could you advise whether this is still considered safe to use in a family home, or should I discard and replace with something else?

Thank you 😊😊

Hello Ali,

I would discard the old straw and start with a fresh new insert for your pouf.

You never know what you’ll find inside lol.

Kim